- Cannabis, both medical and recreational, is the US’ main energy-consuming crop.

- Energy use estimates range between 6 and 580 kWh/kg for greenhouse growing and between 4,400 and 6,100 kWh/kg for indoor production.

- Reducing the massive carbon footprint of indoor-grown cannabis has become an urgent priority for an industry whose impact reaches far beyond cannabis use.

Since 1980, heavy industrial activity has caused CO2 emissions to double. And as scientists warn of the negative impact this can have on the planet, more and more industries are adopting sustainable practices aimed at rectifying the situation.

Many cities in North America have revived as industrial areas thanks to cannabis legalisation, generating billions of dollars in sales. What many don't know is that cannabis production requires massive energy use, which is making these cities abandon their goal of reducing greenhouse effect gases. And with cannabis now being legal in half of U.S states for various uses, indoor production is becoming a growing concern for American governors and mayors.

The carbon footprint of cannabis grow operations

Evan Mills, a scientist from the University of California, was one of the first researchers to quantify the greediness of the industry, estimating that the energy used by indoor-grown cannabis accounts for 1 percent of overall U.S. electricity. According to a study by consulting firm New Frontier Data, this number rises to 3 percent in states like California.

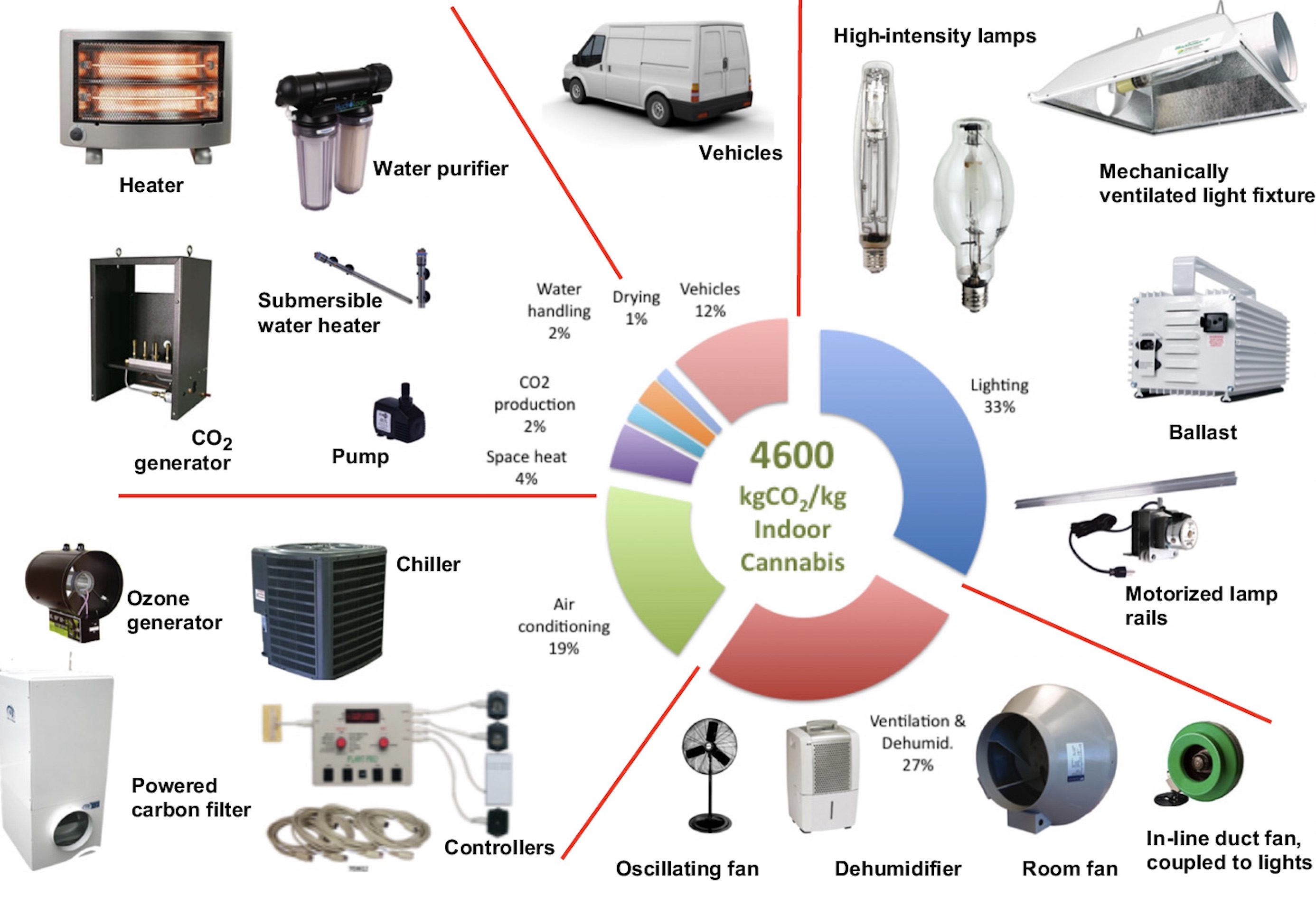

In average, producing a kilogram of indoor-grown cannabis results in 4,600 kg of CO2 emissions. This average is what is known as carbon footprint, a variable that measures the pollution associated to a human activity based on the amount of CO2 it emits.

The carbon footprint of a cannabis kilogram equals that of traveling coast-to-coast across the United States by car seven times, and producing a single joint uses as much energy as leaving a lightbulb on for 25 hours or crafting eight-and-a-half litres of beer.

Who are the main culprits?

The greatest share of responsibility falls to HVAC (Heating, Ventilating and Air conditioning) and lighting systems, which together account for an alarming 89 percent of the energy used in indoor cannabis production.

Last year, legal cannabis cultivation consumed 1.1 million MWh of electricity and produced 472,000 tonnes of CO2 emissions – enough to power 92,500 homes or 92,660 cars for a year.

These figures are mainly down to the methods employed to grow the plant. Indoor production is about 18 times less energy efficient and produces 25 times more emissions of carbon dioxide than outdoor growing methods. On the negative side, open-air cultivation produces lower average yields per square metre, because, of course the environment is not something one can control at will. As a result, many producers are starting to opt for hybrid approaches, combining the benefits of precise control with natural light use to reduce production costs.

An action plan towards sustainability

Many licensed growers are already taking measures aimed at reducing cannabis' huge environmental footprint:

- Renewable energy

Diversifying the energy sources used in the production processes can be a great way to reduce CO2 emissions. Solar and wind power can go a long way in cannabis growing, and in fact, start-ups including Scale Energy Solutions are already combining solar energy with natural gas in a system that can reduce the electricity bill by 35 percent. As part of their energy saving strategy, they use excess heat from generators to power chillers.

- LED lighting

LED lamps are 60 percent more energy efficient than other lighting systems. High pressure sodium lamps, too, are comparatively efficient, but their initial cost per photon is five to ten times higher. Another advantage of LED solutions is that they give off virtually no heat, reducing the need for ventilation.

- Vertical growing

Increasing yields while reducing costs is an ongoing concern for every indoor grower. Maximising the growing space is a great step towards this goal, and it is precisely here that vertical growing – i.e. producing plants in vertically stacked layers – can be of help. Vertical growing optimises the space available, allowing growers to maximise production by stacking the plants in tiers. Generally, this is combined with LED lighting, which reduces electricity use by up to 75 percent compared to high pressure sodium lamps.

- Dehumidification and ventilation

Dehumidifiers and fans rank second in terms of energy use in indoor cannabis production. Many growers overlook their importance when designing their indoor setups, unaware that traditional dehumidifiers release excess heat into the grow room, making the air conditioning work harder. This can be prevented by using a dehumidification system that has been specifically designed not to release heat into the grow space, providing energy savings between 30 and 65 percent.

- Water efficiency

A single adult cannabis plant may need up to 23 litres of water per day. The good news is that this can be recycled and reused through innovative methods like reverse osmosis. GrowX, a company committed to sustainable agriculture, has developed a hydroponic system that incorporates sensors to adjust nutrient doses to the needs of each plant. Another way to reduce water use is, of course, to make sure each plant gets the exact amount it needs for the day, and to capture drained excess water through an underground system. This way the water goes back to the reservoir – after being treated with ozone to remove impurities – and can be reused in the next watering cycle.

- Use of greenhouses

Enhancing the use of artificial light through natural light contributes greatly to energy saving. Providing incentives to greenhouse growers – e.g. for infrared polyethylene covers, which absorb and retain infrared energy ensuring higher night temperatures inside the greenhouse – could encourage producers to take the leap from indoor to greenhouse cultivation.

Is legalisation the answer?

Currently, energy accounts for about half the price of wholesale cannabis, and as prices drop, energy use and production costs will keep rising. As a result, maximising energy-efficiency could have a positive impact not only the planet but also on production costs. This would generate a saving that could be channelled to the buyer, making the industry more competitive as it matures.

Still being in its infancy, however, energy use and carbon footprint within the cannabis industry are expected to keep growing in the next few years, while more eco-friendly technologies are developed and implemented. With this in mind, many believe legalisation could help curb carbon emissions as it would allow to control energy costs, as well as to set consumption thresholds and reward efficient producers.

Unfortunately, there's little legalisation can do without the commitment of policy makers, who continue to ignore the growing energy use associated with cannabis production, putting at risk the strenuous efforts already made to address climate change.

Comments from our readers

Read comments in other languages:

Did you like this post?

Your opinion about our seeds is very important to us and can help other users a lot (your email address won't be made public).